Content Menu

● Understanding Electric Fuel Pumps

>> Types of Electric Fuel Pumps

● Tools and Materials Needed

● Step-by-Step Installation Guide

>> Step 1: Safety First

>> Step 2: Remove the Old Fuel Pump

>> Step 3: Prepare for New Pump Installation

>> Step 4: Install the Electric Fuel Pump

>> Step 5: Wiring the Electric Fuel Pump

>> Step 6: Testing Your Installation

● Maintenance Tips for Your Electric Fuel Pump

● Benefits of Upgrading to an Electric Fuel Pump

● Additional Considerations When Installing an Electric Fuel Pump

>> Choosing The Right Location for Your Pump

>> Wiring Considerations

>> Understanding Pressure Regulation

● Troubleshooting Common Issues

● Advanced Modifications for Enhanced Performance

>> Upgrading Fuel Lines

>> Adding a High-Efficiency Carburetor

● Final Thoughts

● Frequently Asked Questions (FAQ)

>> 1. Can I use any electric fuel pump for my golf cart?

>> 2. How do I know if my electric fuel pump is working?

>> 3. What should I do if my engine stalls after installing an electric fuel pump?

>> 4. Is it necessary to disconnect my battery before installation?

>> 5. How often should I check my electric fuel pump?

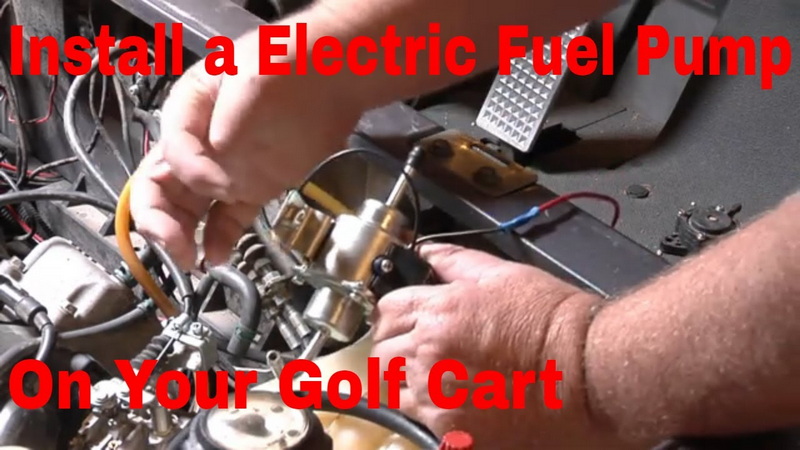

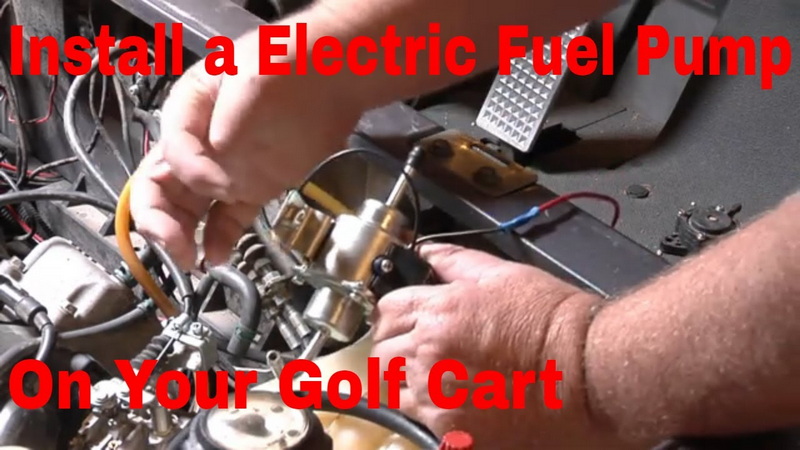

Installing an electric fuel pump on a golf cart can significantly improve its performance, especially if the existing mechanical fuel pump is failing. This guide will walk you through the steps to successfully install an electric fuel pump, including necessary tools, wiring instructions, and troubleshooting tips.

Understanding Electric Fuel Pumps

Electric fuel pumps are designed to deliver fuel from the tank to the engine at a consistent pressure. They typically operate at a pressure of around 2-4 PSI, which is sufficient for most golf cart engines. When considering an electric fuel pump, it's essential to ensure compatibility with your specific golf cart model.

Types of Electric Fuel Pumps

There are generally two types of electric fuel pumps:

- In-Line Pumps: These are installed along the fuel line and can be used in various applications. They are versatile and can be mounted in different positions.

- Submersible Pumps: These are placed directly inside the fuel tank. They are quieter and more efficient but require more complex installation.

Choosing the right type depends on your golf cart's design and your personal preference.

Tools and Materials Needed

Before starting the installation process, gather the following tools and materials:

- Electric fuel pump (2-4 PSI)

- Fuel hose (appropriate diameter)

- Hose clamps

- Wire connectors

- Electrical tape

- Wrench set

- Screwdriver set

- Wire stripper/cutter

- Safety goggles and gloves

- Fuel filter (optional but recommended)

- Relay switch (for better control)

Step-by-Step Installation Guide

Step 1: Safety First

Before you begin, ensure that the golf cart is turned off and parked on a flat surface. Disconnect the battery to prevent any electrical accidents during installation.

Step 2: Remove the Old Fuel Pump

1. Locate the existing mechanical fuel pump on your golf cart. It is usually mounted on or near the engine.

2. Disconnect the fuel lines attached to the old pump. Be prepared for some fuel spillage; have a container ready to catch any leaking fuel.

3. Remove any bolts or screws securing the old pump in place and take it out.

Step 3: Prepare for New Pump Installation

1. Inspect the area where the new pump will be installed. Clean any debris or old gasket material that may interfere with the new installation.

2. If necessary, block off any vacuum lines that were connected to the old mechanical pump.

Step 4: Install the Electric Fuel Pump

1. Position the electric fuel pump in a suitable location, ensuring it is close to the fuel tank and engine.

2. Use bolts or brackets to secure the pump in place.

3. Connect the input line from the fuel tank to the inlet of the electric pump.

4. Attach a hose from the outlet of the electric pump to the carburetor.

Step 5: Wiring the Electric Fuel Pump

1. Identify a suitable power source for your electric pump. It is recommended to connect it to a wire that receives power only when the engine is running (such as from the ignition switch or solenoid).

- Important: Ensure that this wire can handle the current required by your pump.

2. Use wire connectors to attach one wire from your electric pump to this power source.

3. Connect the other wire from your electric pump to a good ground point on your golf cart's frame.

Step 6: Testing Your Installation

1. Reconnect your battery and turn on your golf cart.

2. Listen for a humming sound from the fuel pump, indicating it is functioning correctly.

3. Check for any leaks around connections and hoses.

4. Start your golf cart and observe its performance.

Maintenance Tips for Your Electric Fuel Pump

To ensure longevity and optimal performance of your electric fuel pump, consider these maintenance tips:

- Regular Inspections: Periodically check all connections for tightness and inspect hoses for wear or damage.

- Fuel Quality: Use clean, high-quality fuel to prevent clogging or damage to your pump over time.

- Filter Replacement: If your system includes a fuel filter, replace it regularly according to manufacturer recommendations.

- Listen for Noise: An unusual noise from your fuel pump can indicate issues; if you hear grinding or excessive noise, inspect it immediately.

Benefits of Upgrading to an Electric Fuel Pump

Upgrading from a mechanical to an electric fuel pump offers several benefits:

- Improved Performance: Electric pumps provide more consistent pressure, leading to better engine performance.

- Increased Reliability: Electric pumps tend to be more reliable than mechanical ones, especially in varying terrain conditions common in golf carts.

- Easier Starting: With better pressure delivery, starting your engine becomes easier, especially in colder weather conditions.

Additional Considerations When Installing an Electric Fuel Pump

To further enhance this guide, let's delve into some additional considerations that may affect your installation process:

Choosing The Right Location for Your Pump

The placement of your electric fuel pump is crucial for its efficiency:

- Proximity to Fuel Tank: The closer you can mount it to the tank without compromising accessibility and safety, the better it will perform due to reduced strain on its motor.

- Vibration Isolation: Ensure that it is mounted securely but not rigidly; consider using rubber mounts or cushions to absorb vibrations which can lead to premature failure of both hoses and pumps over time.

Wiring Considerations

When wiring your new electric fuel pump:

- Fuse Protection: Always include an inline fuse rated appropriately for your setup (usually between 5A - 15A) close to where you tap into power from your ignition switch or battery; this protects against potential shorts which could damage both wiring and components.

- Wire Gauge: Use appropriately sized wiring based on distance from power source; typically AWG 16 is sufficient but consult manufacturer specifications if unsure about load requirements.

Understanding Pressure Regulation

Some systems may require additional pressure regulation depending on engine modifications:

- If you have upgraded components such as carburetors or injectors that demand higher flow rates than stock parts provide, consider adding a pressure regulator between your outlet line from the electric pump and carburetor/injector assembly.

Troubleshooting Common Issues

If you encounter problems after installation:

- Pump Not Working: Check all electrical connections for tightness and ensure there's power reaching the pump.

- Fuel Leaks: Inspect all hose connections and clamps for tightness; replace any damaged hoses.

- Engine Performance Issues: Ensure that you're using a pump with appropriate PSI ratings for your specific golf cart model.

Advanced Modifications for Enhanced Performance

For those looking to push their golf cart's performance further, consider these advanced modifications alongside installing an electric fuel pump:

Upgrading Fuel Lines

Replacing old or damaged fuel lines with high-performance alternatives can reduce resistance and improve flow rates:

- Material Choice: Opt for rubber or nylon lines designed specifically for automotive use; these materials resist degradation from fuels better than standard hoses.

Adding a High-Efficiency Carburetor

If you're upgrading your fueling system, pairing an electric pump with a high-efficiency carburetor can yield significant performance gains:

- Look for carburetors designed specifically for performance applications which offer better atomization of fuel leading to improved combustion efficiency in engines.

Final Thoughts

The process of installing an electric fuel pump may seem daunting at first glance but breaking it down into manageable steps makes it achievable even for those with limited mechanical experience. With careful planning, proper tools at hand, and adherence to safety protocols outlined above, you can enhance not just how well your golf cart runs but also enjoy peace of mind knowing you've taken steps towards improving its overall functionality and reliability on every outing!

Frequently Asked Questions (FAQ)

1. Can I use any electric fuel pump for my golf cart?

- Not all pumps are suitable; ensure you choose one rated for low pressure (2-4 PSI) compatible with your engine type.

2. How do I know if my electric fuel pump is working?

- You should hear a humming sound when it's powered on, and check for proper fuel delivery when starting your engine.

3. What should I do if my engine stalls after installing an electric fuel pump?

- Check all connections for leaks or air pockets in the fuel line; ensure that there's no blockage preventing fuel flow.

4. Is it necessary to disconnect my battery before installation?

- Yes, always disconnect your battery before working on electrical components to avoid shocks or shorts.

5. How often should I check my electric fuel pump?

- Regularly inspect it during routine maintenance checks, especially before long trips or after prolonged periods of inactivity.