Content Menu

● Understanding Overheating in Electric Golf Cart Motors

● Tools Required for Rebuilding an Electric Golf Cart Motor

● Step-by-Step Guide to Rebuilding Your Golf Cart Motor

>> Preparation

>> Disconnect Power

>> Remove the Motor

>> Disassemble the Motor

>> Inspect Components

>> Clean All Parts

>> Reassemble the Motor

>> Test the Motor

● Preventive Maintenance Tips

● Conclusion

● FAQ

>> 1. How do I know if my golf cart motor is overheating?

>> 2. Can I rebuild my golf cart motor myself?

>> 3. What parts should I replace when rebuilding my electric golf cart motor?

>> 4. How often should I perform maintenance on my electric golf cart?

>> 5. What should I do if my rebuilt motor still has problems?

Electric golf carts are a popular choice for many golf enthusiasts and recreational users due to their quiet operation and ease of use. However, like any mechanical device, they can experience issues over time, particularly with their motors. One common problem is overheating, which can lead to significant damage if not addressed promptly. This article will guide you through the process of rebuilding an overheated electric golf cart motor, including essential tools, steps for disassembly and reassembly, testing procedures, and maintenance tips to prevent future issues.

Understanding Overheating in Electric Golf Cart Motors

Overheating in electric golf cart motors can be caused by several factors:

- Continuous Use: Extended periods of operation without breaks can lead to excessive heat buildup.

- Electrical Issues: Problems such as short circuits or faulty wiring can increase resistance and generate heat.

- Mechanical Failures: Worn bearings or misaligned components can create friction, leading to overheating.

- Poor Ventilation: If the motor is not adequately ventilated, heat can accumulate quickly.

Recognizing the signs of an overheating motor early on—such as unusual noises, reduced performance, or burning smells—can help prevent more severe damage.

Tools Required for Rebuilding an Electric Golf Cart Motor

Before starting the rebuilding process, gather the following tools:

- Socket Set: For removing bolts and nuts.

- Torque Wrench: To ensure bolts are tightened to manufacturer specifications.

- Screwdrivers: Both flathead and Phillips for disassembly.

- Rubber Mallet: To gently tap parts into place.

- Pliers: For gripping and manipulating small components.

- Wire Brush and Cleaning Solvent: To clean parts before reassembly.

- Multimeter: For testing electrical components.

Step-by-Step Guide to Rebuilding Your Golf Cart Motor

Preparation

Start by ensuring you have a clean workspace with good lighting. Gather all necessary tools and materials, including replacement parts if needed.

Disconnect Power

Safety first! Disconnect the battery from the golf cart to prevent any electrical accidents during the rebuilding process.

Remove the Motor

- Locate the motor in your golf cart.

- Identify and remove any mounting bolts or brackets securing it in place using your socket set.

- Carefully disconnect any electrical connections attached to the motor.

- Once all connections are detached, gently lift the motor out of the cart using a hoist or jack if necessary.

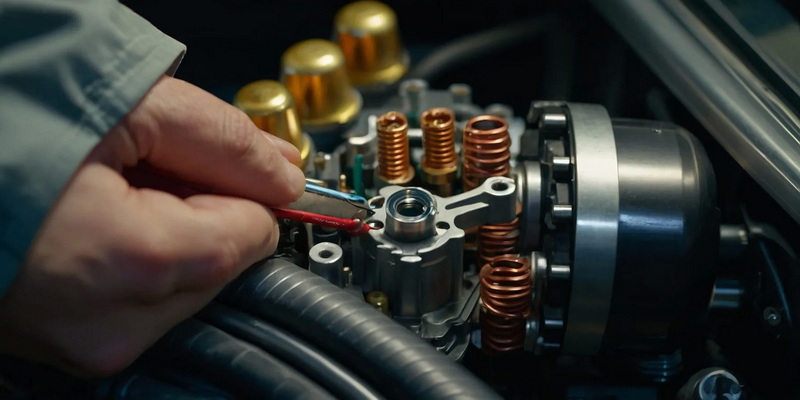

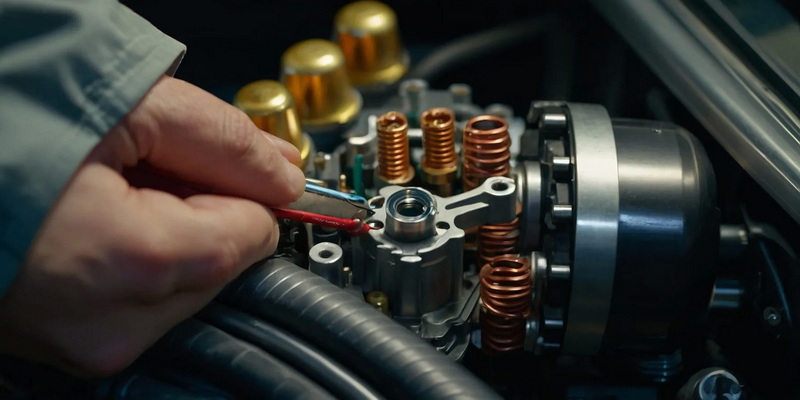

Disassemble the Motor

- Begin by removing screws and bolts holding the motor casing together.

- Take note of how components are arranged for easier reassembly later.

- Carefully remove the casing to expose the internal parts of the motor.

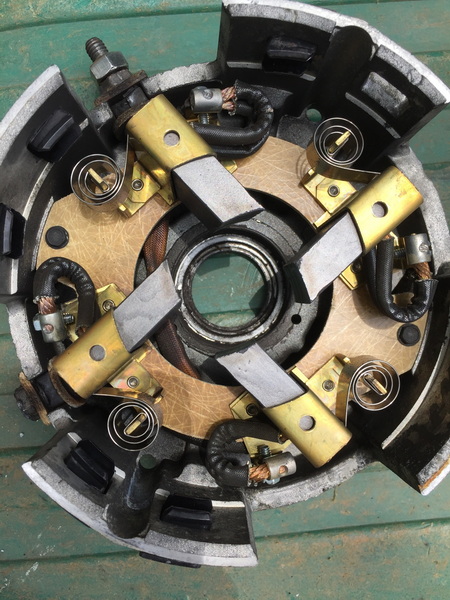

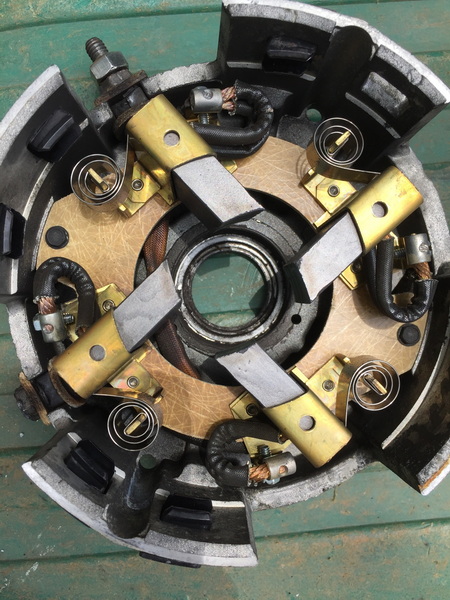

Inspect Components

Once disassembled, inspect all parts for signs of wear or damage:

- Armature: Check for burn marks or warping.

- Brushes: Look for excessive wear; they may need replacement.

- Bearings: Ensure they are not worn out or damaged.

If you find any damaged components, replace them with compatible parts before proceeding.

Clean All Parts

Using a soft brush or compressed air, clean all internal parts thoroughly to remove dirt and debris. This step is crucial for optimal performance after reassembly.

Reassemble the Motor

Carefully reassemble the motor in reverse order of disassembly:

- Ensure that all components fit snugly and securely.

- Use a torque wrench to tighten bolts to manufacturer specifications.

Test the Motor

Once reassembled, it's essential to test your motor:

1. Reconnect it to a power source.

2. Observe its performance under load conditions.

3. Listen for unusual noises that may indicate issues.

Preventive Maintenance Tips

To avoid future overheating issues with your electric golf cart motor:

- Regular Inspections: Periodically check your motor for signs of wear or damage.

- Proper Ventilation: Ensure that your golf cart's motor area is well ventilated during operation.

- Limit Continuous Use: Take breaks during long periods of use to allow the motor to cool down.

- Battery Maintenance: Regularly check battery levels and connections as poor battery performance can strain the motor.

Conclusion

Rebuilding an overheated electric golf cart motor is a feasible task if approached methodically with the right tools and knowledge. By following these steps carefully, you can restore your golf cart's performance and extend its lifespan. Remember that regular maintenance is key to preventing future issues, ensuring that your electric golf cart remains reliable for years to come.

FAQ

1. How do I know if my golf cart motor is overheating?

Signs include unusual noises, a burning smell, reduced performance, or visible damage on the motor casing.

2. Can I rebuild my golf cart motor myself?

Yes, with proper tools and knowledge about disassembly and reassembly processes, you can rebuild your motor yourself. However, if you're unsure, consider seeking professional help.

3. What parts should I replace when rebuilding my electric golf cart motor?

Common parts that may need replacement include brushes, bearings, and any damaged wiring or components within the motor assembly.

4. How often should I perform maintenance on my electric golf cart?

Regular maintenance should be conducted at least once every few months or more frequently if you use your cart often or notice performance issues.

5. What should I do if my rebuilt motor still has problems?

If issues persist after rebuilding your motor, it may be best to consult a professional technician who specializes in electric motors for further diagnosis and repair.