Content Menu

● Tools Needed for Testing

● Step-by-Step Guide to Testing an Electric Golf Cart Motor

>> Safety First

>> Visual Inspection

>> Check Voltage with a Multimeter

>> Test for Continuity

>> Measure Power Output

>> Bench Testing

>> Testing for Shorts

● Common Issues with Golf Cart Motors

>> Motor Won't Start

>> Poor Performance

>> Unusual Noises

>> Overheating

>> Inconsistent Speed Control

● Conclusion

● Related Questions

>> 1. How often should I test my golf cart motor?

>> 2. What should I do if my multimeter shows no voltage?

>> 3. Can I test my golf cart motor without removing it?

>> 4. What are common signs that my golf cart motor needs replacement?

>> 5. Is it safe to work on an electric golf cart?

Testing an electric golf cart motor is essential for maintaining the performance and safety of your vehicle. A well-functioning motor ensures that your golf cart operates smoothly and efficiently, while a malfunctioning motor can lead to poor performance or complete failure. In this guide, we will explore the steps involved in testing a golf cart electric motor, the tools required, and common issues you may encounter.

Tools Needed for Testing

Before you begin testing your golf cart motor, gather the following tools:

- Multimeter

- Power source (battery or power supply)

- Jumper cables

- Screwdriver

- Safety gloves and goggles

Step-by-Step Guide to Testing an Electric Golf Cart Motor

Safety First

Before starting any work on your golf cart, ensure it is turned off and the key is removed. Wear safety gloves and goggles to protect yourself from any electrical hazards.

Visual Inspection

Begin with a thorough visual inspection of the motor and surrounding components:

- Check for any visible damage, such as frayed wires or burnt components.

- Ensure all connections are secure and free from corrosion.

- Look for signs of wear on brushes and commutators.

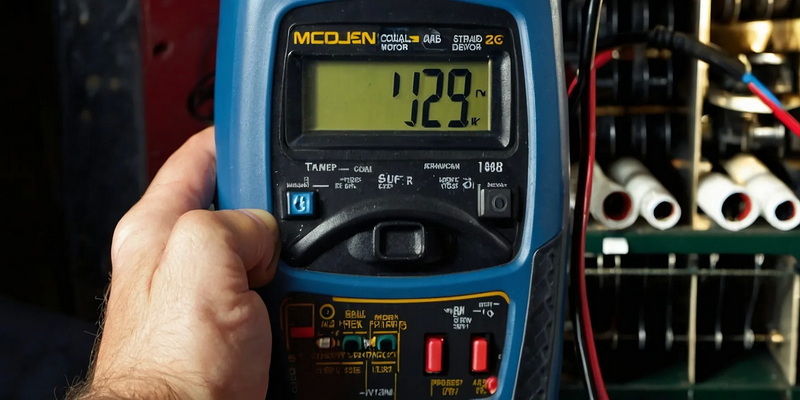

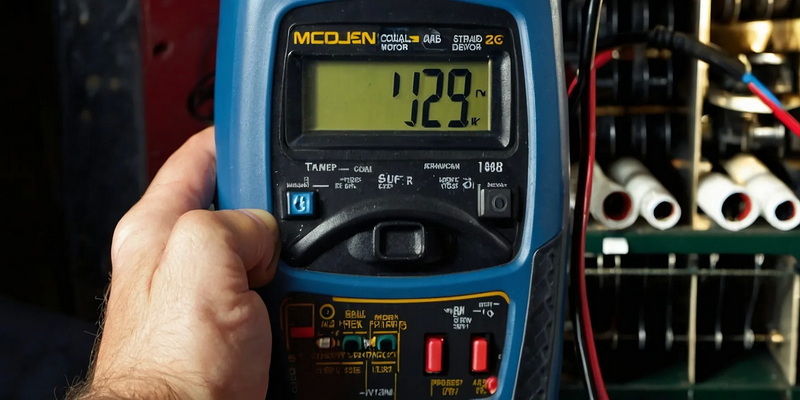

Check Voltage with a Multimeter

To test the voltage of the electric motor:

- Set your multimeter to the voltage setting.

- Locate the positive and negative terminals of the motor.

- Connect the red lead of the multimeter to the positive terminal and the black lead to the negative terminal.

- Turn on the multimeter and check if the voltage falls within the manufacturer's specifications (typically between 36 and 48 volts) [1].

Test for Continuity

Next, you'll want to check for continuity in the motor's windings:

- Set your multimeter to the continuity setting.

- Place the probes on two specific points of the motor (e.g., A1 & A2).

- A beep or reading close to zero indicates good continuity. If not, there may be a break in the winding [3].

Measure Power Output

To measure power output:

- Connect your motor to a power source using jumper cables.

- Use a power meter to measure voltage and current.

- Calculate power output using the formula:

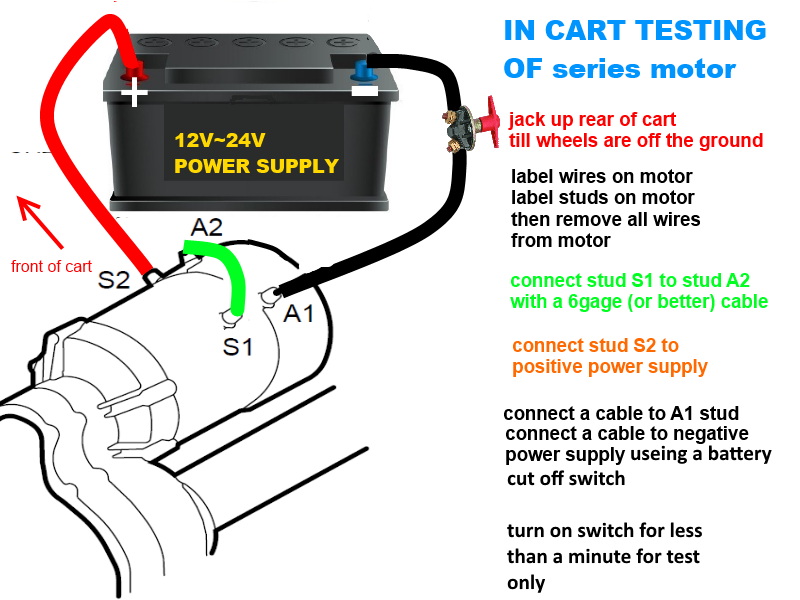

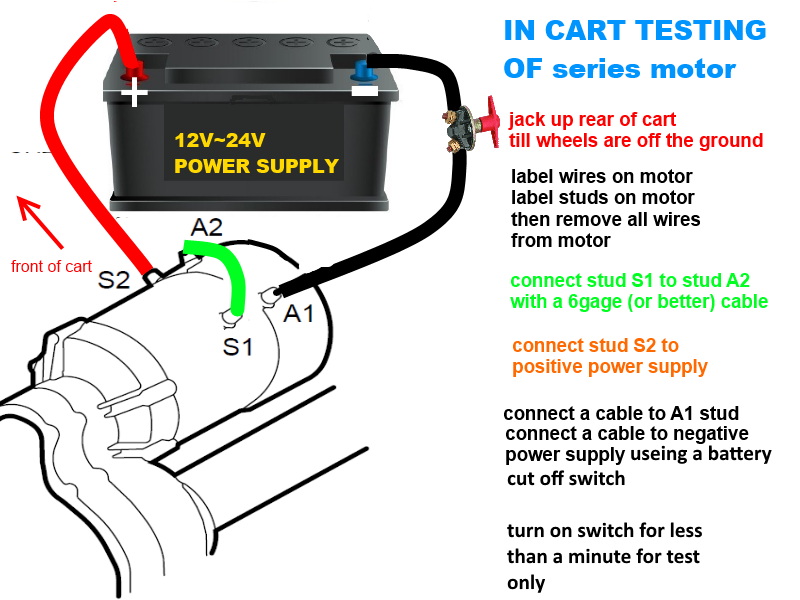

Bench Testing

If you want to conduct a more thorough test, consider bench testing:

- Disconnect the motor from its electrical system.

- Secure it on a stable workbench.

- Connect it to a power source while monitoring its performance for unusual noises or vibrations [5].

Testing for Shorts

To ensure there are no internal shorts within the motor:

- Set your multimeter to continuity mode.

- Test between different terminals (e.g., A1 & S1) to check for continuity where there should be none; this indicates a short [3][7].

Common Issues with Golf Cart Motors

While testing your golf cart's electric motor, you may encounter several common issues:

Motor Won't Start

If your golf cart doesn't start, it could be due to:

- Dead batteries

- Faulty solenoid

- Loose connections

Poor Performance

If your golf cart runs but lacks power, check for:

- Worn brushes

- Corroded terminals

- Insufficient voltage supply

Unusual Noises

Grinding or squeaking noises may indicate:

- Worn bearings

- Misalignment of components

- Debris in the motor

Overheating

If the motor overheats during operation:

- Ensure proper ventilation around the motor.

- Check for excessive load or resistance in wiring.

Inconsistent Speed Control

If your golf cart does not maintain speed:

- Inspect speed control potentiometer connections.

- Test for faults in wiring or controller.

Conclusion

Testing an electric golf cart motor is crucial for ensuring its reliability and performance. By following these steps, you can identify potential issues early and maintain your golf cart in optimal condition. Regular maintenance checks can prolong the life of your electric motor and enhance your overall golfing experience.

Related Questions

1. How often should I test my golf cart motor?

Regular testing every six months is recommended, especially before peak usage seasons.

2. What should I do if my multimeter shows no voltage?

Check all connections, ensure that batteries are charged, and inspect for any blown fuses.

3. Can I test my golf cart motor without removing it?

Yes, you can perform basic tests like checking voltage and continuity without removing it.

4. What are common signs that my golf cart motor needs replacement?

Unusual noises, overheating, poor performance, or failure to start are indicators that replacement may be necessary.

5. Is it safe to work on an electric golf cart?

Yes, as long as you take proper precautions such as disconnecting power sources and wearing safety gear.