Content Menu

● The Basics of Golf Cart Electric Motors

● Components of a Golf Cart Electric Motor System

● The Role of the Forward/Reverse Switch

● How Reverse Motion is Achieved

● The Science Behind Current Reversal

● The Role of the Motor Controller

● Safety Features in Reverse Operation

● Maintenance for Reliable Reverse Operation

● Advancements in Golf Cart Reverse Technology

● Environmental Impact of Electric Golf Carts

● Comparing AC and DC Motors in Reverse Operation

● The Future of Golf Cart Reverse Technology

● Conclusion

● FAQ

>> 1. How fast can a golf cart go in reverse?

>> 2. Can I upgrade my golf cart to improve its reverse performance?

>> 3. Why does my golf cart make a beeping sound when in reverse?

>> 4. How do I troubleshoot if my golf cart won't go in reverse?

>> 5. Are there any special considerations for using reverse on hills?

Golf carts have become an essential mode of transportation in various settings, from golf courses to residential communities. One of the key features that make these vehicles versatile is their ability to move both forward and backward. In this comprehensive article, we'll explore the fascinating mechanics behind how a golf cart electric motor goes in reverse, delving into the components, processes, and technologies that enable this crucial function.

The Basics of Golf Cart Electric Motors

Before we dive into the specifics of reverse motion, it's important to understand the fundamental workings of a golf cart electric motor. Electric golf carts typically use DC (Direct Current) motors, although some modern models are now incorporating AC (Alternating Current) motors for improved efficiency and performance.

The electric motor in a golf cart converts electrical energy from the batteries into mechanical energy, which propels the vehicle. This conversion process involves the interaction between electromagnetic fields created by the motor's components.

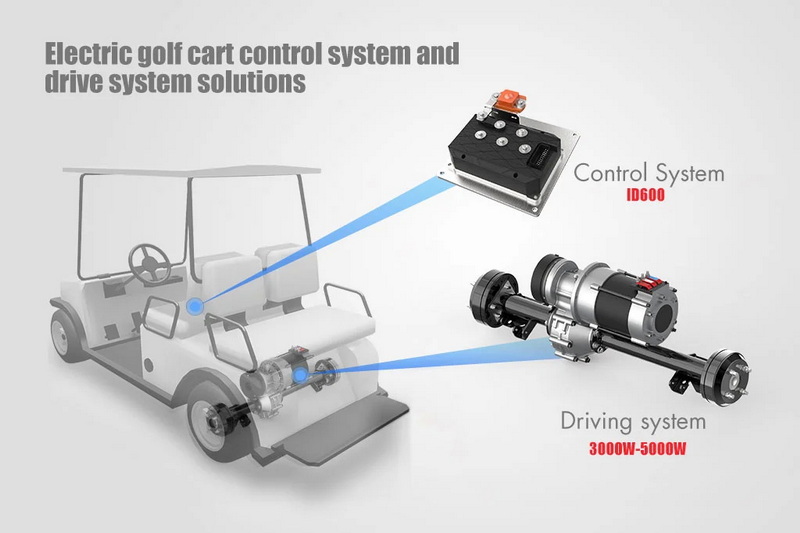

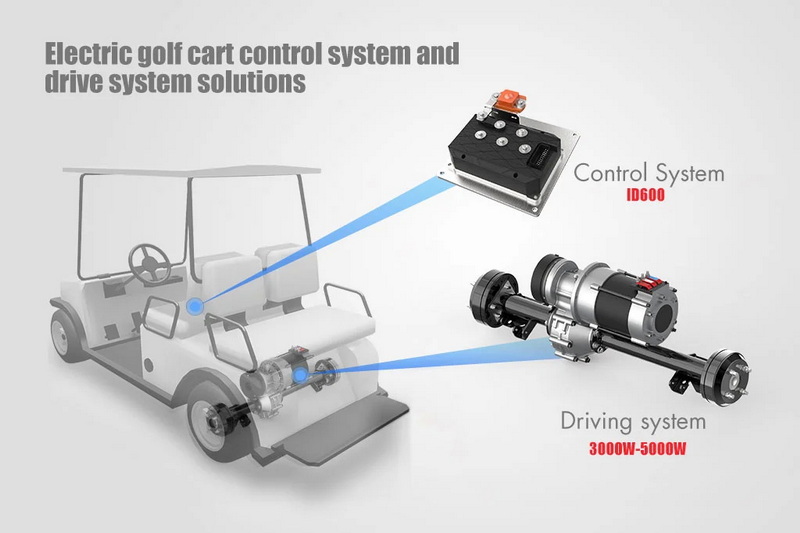

Components of a Golf Cart Electric Motor System

To understand how a golf cart goes in reverse, we need to familiarize ourselves with the key components involved:

1. Batteries

2. Motor controller

3. Electric motor

4. Forward/Reverse switch

5. Accelerator pedal

Each of these components plays a crucial role in the overall operation of the golf cart, including its ability to move in reverse.

The Role of the Forward/Reverse Switch

The forward/reverse switch, also known as the F/R switch, is the primary component responsible for changing the direction of the golf cart. This switch is typically located near the driver's seat or on the dashboard, easily accessible to the operator.

When the switch is moved to the reverse position, it triggers a series of electrical changes within the motor system, ultimately resulting in the reversal of the motor's rotation.

How Reverse Motion is Achieved

The process of reversing a golf cart's electric motor involves changing the direction of current flow through the motor. Here's a step-by-step breakdown of how this occurs:

1. The driver moves the F/R switch to the reverse position.

2. This action sends a signal to the motor controller.

3. The motor controller reverses the polarity of the current flowing to the motor.

4. The reversed current causes the motor to rotate in the opposite direction.

5. This reversed rotation is transferred to the wheels, moving the golf cart backward.

It's important to note that the actual reversal of current is handled by the motor controller, not the F/R switch itself. The switch simply signals the controller to make the necessary changes.

The Science Behind Current Reversal

To understand why reversing the current causes the motor to rotate in the opposite direction, we need to delve into some basic electromagnetic principles.

In a DC motor, the interaction between two magnetic fields causes rotation:

1. The stationary magnetic field created by permanent magnets or electromagnets in the motor housing.

2. The rotating magnetic field created by the current flowing through the armature windings.

When the current direction is reversed, it changes the polarity of the rotating magnetic field. This causes the armature to rotate in the opposite direction, effectively reversing the motor's motion.

The Role of the Motor Controller

The motor controller is a crucial component in the reverse operation of a golf cart. It acts as the brain of the electric drive system, interpreting signals from the F/R switch and accelerator pedal, and controlling the flow of current to the motor.

When the F/R switch is moved to the reverse position, the controller performs several functions:

1. It cuts off the current to the motor momentarily.

2. It then reverses the connections to the motor's field windings or armature.

3. Finally, it reapplies the current in the opposite direction.

This process happens almost instantaneously, allowing for smooth transitions between forward and reverse motion.

Safety Features in Reverse Operation

Golf cart manufacturers incorporate various safety features to prevent accidents during reverse operation. Some of these include:

1. Automatic speed limitation in reverse

2. Reverse warning beepers

3. Rearview mirrors or cameras

These features help ensure that reverse operation is as safe as possible, reducing the risk of collisions or injuries.

Maintenance for Reliable Reverse Operation

To ensure your golf cart's reverse function continues to operate smoothly, regular maintenance is essential. This includes:

1. Checking and cleaning the F/R switch contacts

2. Inspecting wiring connections

3. Testing the motor controller

4. Lubricating moving parts in the drivetrain

Regular maintenance not only ensures reliable reverse operation but also extends the overall lifespan of your golf cart.

Advancements in Golf Cart Reverse Technology

As technology continues to advance, so do the systems controlling golf cart reverse operations. Some recent innovations include:

1. Electronic shift-by-wire systems

2. Regenerative braking in reverse

3. Smart reverse assist features

These advancements are making golf carts safer, more efficient, and easier to operate in reverse.

Environmental Impact of Electric Golf Carts

It's worth noting that electric golf carts, including their reverse capabilities, have a significantly lower environmental impact compared to their gas-powered counterparts. They produce zero direct emissions and are generally more energy-efficient.

The ability to reverse efficiently also contributes to this eco-friendliness by reducing the need for wide turning circles and allowing for more precise maneuvering.

Comparing AC and DC Motors in Reverse Operation

While DC motors have been the standard in golf carts for many years, AC motors are becoming increasingly popular. Both types of motors can operate in reverse, but there are some differences:

1. DC motors typically use a simpler reversal mechanism.

2. AC motors often provide smoother acceleration in reverse.

3. AC systems can be more efficient overall, including in reverse operation.

The choice between AC and DC motors can affect the reverse performance of a golf cart, with each type offering its own advantages.

The Future of Golf Cart Reverse Technology

Looking ahead, we can expect to see continued advancements in golf cart reverse technology. Some potential developments include:

1. AI-assisted reverse maneuvering

2. Enhanced safety sensors for reverse operation

3. Integration with smart course management systems

These innovations promise to make reverse operation even safer and more efficient in the future.

Conclusion

The ability of a golf cart electric motor to go in reverse is a testament to the ingenuity of electric vehicle design. Through the coordinated action of the forward/reverse switch, motor controller, and the motor itself, golf carts can smoothly transition between forward and backward motion. This capability not only enhances the versatility of these vehicles but also contributes to their safety and efficiency.

As technology continues to advance, we can expect to see even more sophisticated reverse systems in golf carts, further improving their performance and user experience. Whether you're navigating a tight spot on the golf course or maneuvering in a residential community, understanding how your golf cart goes in reverse can help you appreciate and utilize this essential function more effectively.

FAQ

1. How fast can a golf cart go in reverse?

Most golf carts are designed to move slower in reverse than in forward motion for safety reasons. Typically, the reverse speed is limited to about 5-10 mph (8-16 km/h), depending on the model and manufacturer. Some golf carts may have adjustable speed limiters for reverse operation.

2. Can I upgrade my golf cart to improve its reverse performance?

Yes, there are several upgrades you can consider to improve your golf cart's reverse performance:

- Installing a more powerful motor

- Upgrading the motor controller

- Replacing worn-out batteries

- Installing high-performance tires for better traction

However, it's important to consult with a professional or the manufacturer before making any significant modifications to ensure safety and compatibility.

3. Why does my golf cart make a beeping sound when in reverse?

The beeping sound you hear when your golf cart is in reverse is a safety feature known as a reverse warning beeper. This audible alert is designed to warn nearby pedestrians or other vehicles that your cart is moving backward, helping to prevent accidents. It's a standard safety feature on many modern golf carts.

4. How do I troubleshoot if my golf cart won't go in reverse?

If your golf cart won't go in reverse, you can try the following troubleshooting steps:

1. Check the battery charge level

2. Inspect the forward/reverse switch for damage or loose connections

3. Examine the motor and controller for any visible issues

4. Test the reverse solenoid if your cart has one

5. Consult the user manual for model-specific troubleshooting steps

If these steps don't resolve the issue, it's best to have a professional technician inspect your golf cart.

5. Are there any special considerations for using reverse on hills?

Using reverse on hills requires extra caution. Here are some tips:

- Avoid reversing uphill if possible, as it puts extra strain on the motor

- When reversing downhill, use the brake to control your speed

- Be aware of your surroundings and any obstacles

- Ensure your batteries are well-charged before attempting to reverse on hills

- If your cart has a regenerative braking system, it may provide additional control when reversing downhill

Always prioritize safety and consult your golf cart's manual for specific guidelines on hill operation.